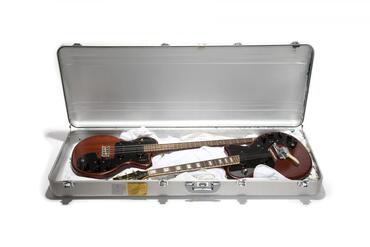

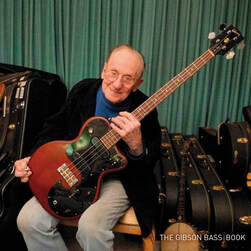

In 2008 I bought this weird Gibson bass off Ebay via a good friend in Germany. Nowadays I happen to know a thing or two about Gibson bass guitars, but at that time it wasn't exactly clear whether it was either an employee build or an unknown prototype. But it looked legit to me. The way the lacquer had aged, the shape of the headstock, the logo, the neck, the rosewood fretboard and the fretless wonder frets, the electronics. No doubt in my mind it was a real Gibson.

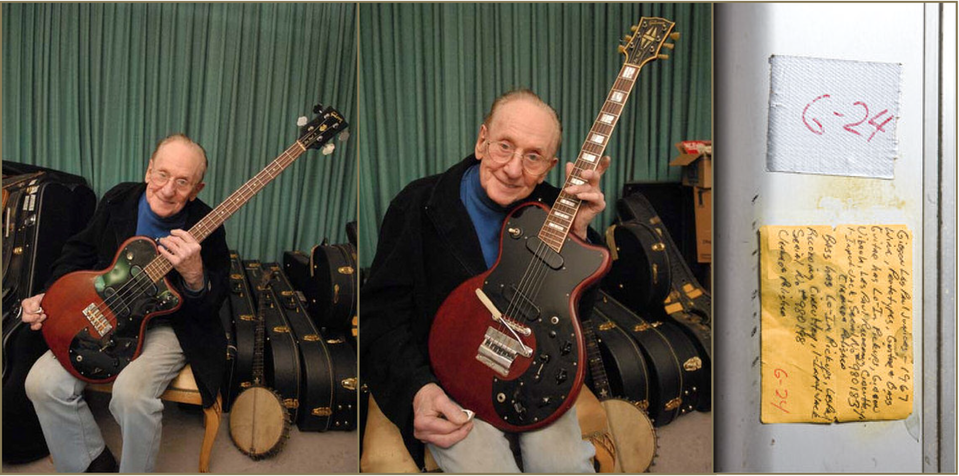

But there were some weird things going on. The serial number had been scratched out and partly filled with some kind of bondo. The bass featured a Badass bridge that was partly recessed into the body. And aftermarket black tuners.

But I bought it anyway.

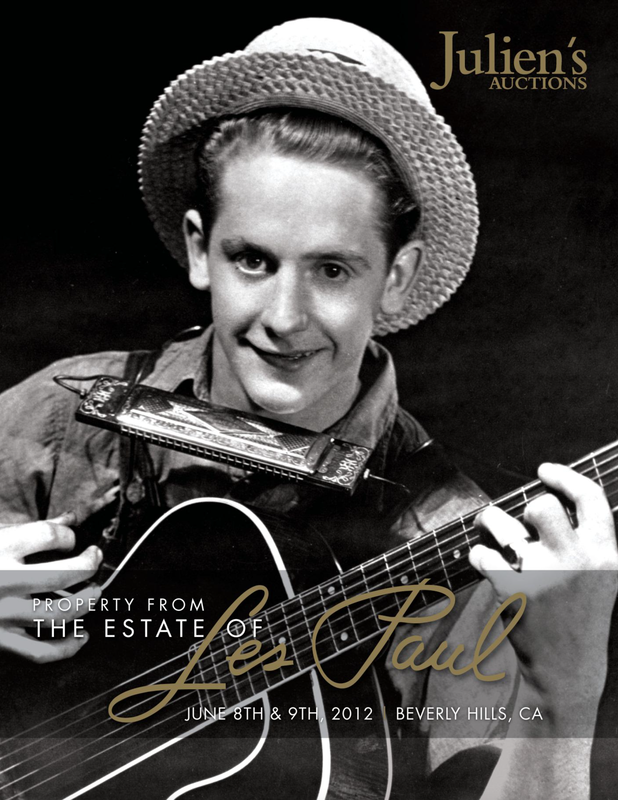

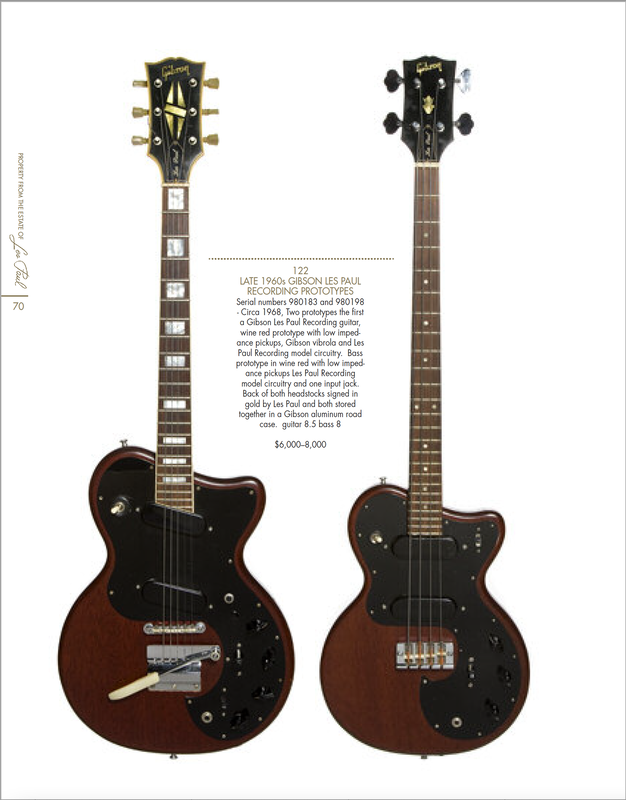

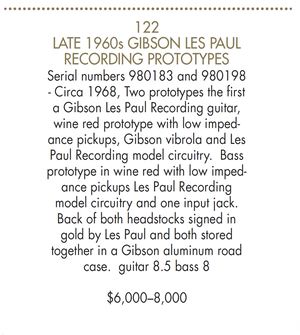

And a couple of years later (in 2012) I discovered another one exactly like mine in the auction brochure of the Les Paul estate auction. It was sold together with a Gibson guitar that had the exact same body shape.

Then I knew for sure it was a genuine Gibson Les Paul prototype and not just some weird employee build or homemade thing.

And I have theory what happened to this bass.

Near the neck joint there are tell tale signs of a repaired neck joint. The neck had not been removed by heating the glue, like you normally would when you want to remove a set neck. But the neck was brutally severed from its body by a strong impact. Like someone deliberately smashed it in two.

What could be the reason for destroying this bass? I think the neck angle was the reason. It is the wrong way around!

The body normally tilts back a bit in order for the bridge to allow for a decent action. But on this bass it tilts forward. Someone f*cked up at the Gibson factory...

So Gibson rejected this prototype, removed the serial number (to prevent it from being sold?) and threw it in the bin. Then

someone fished it out of the bin, took it home and glued the neck back. The glue seams are very nice and there's hardly any wood missing. Except on the top a few splinters maybe. A real clean and solid repair.

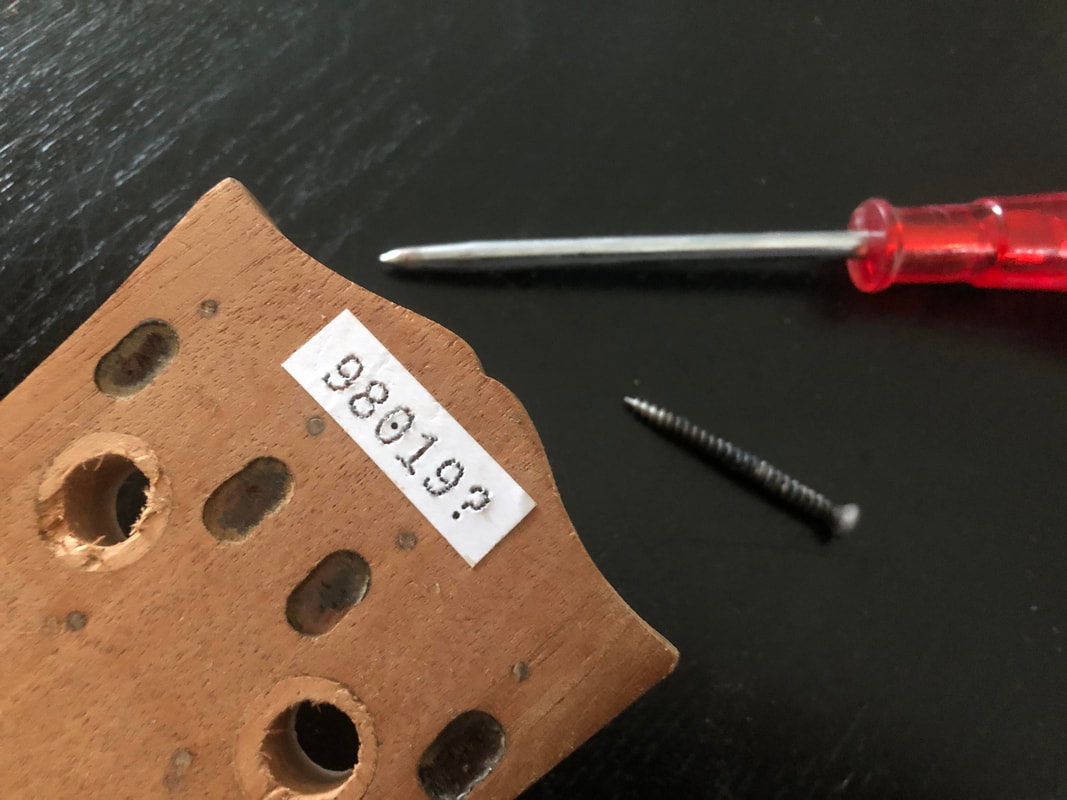

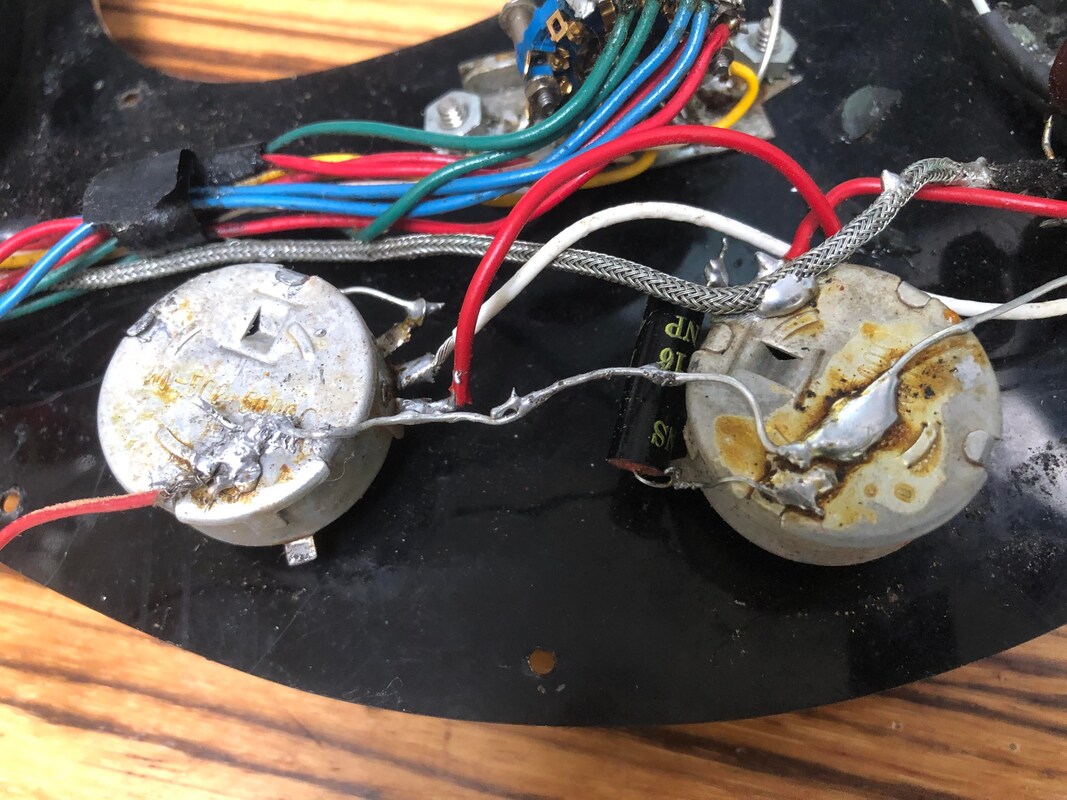

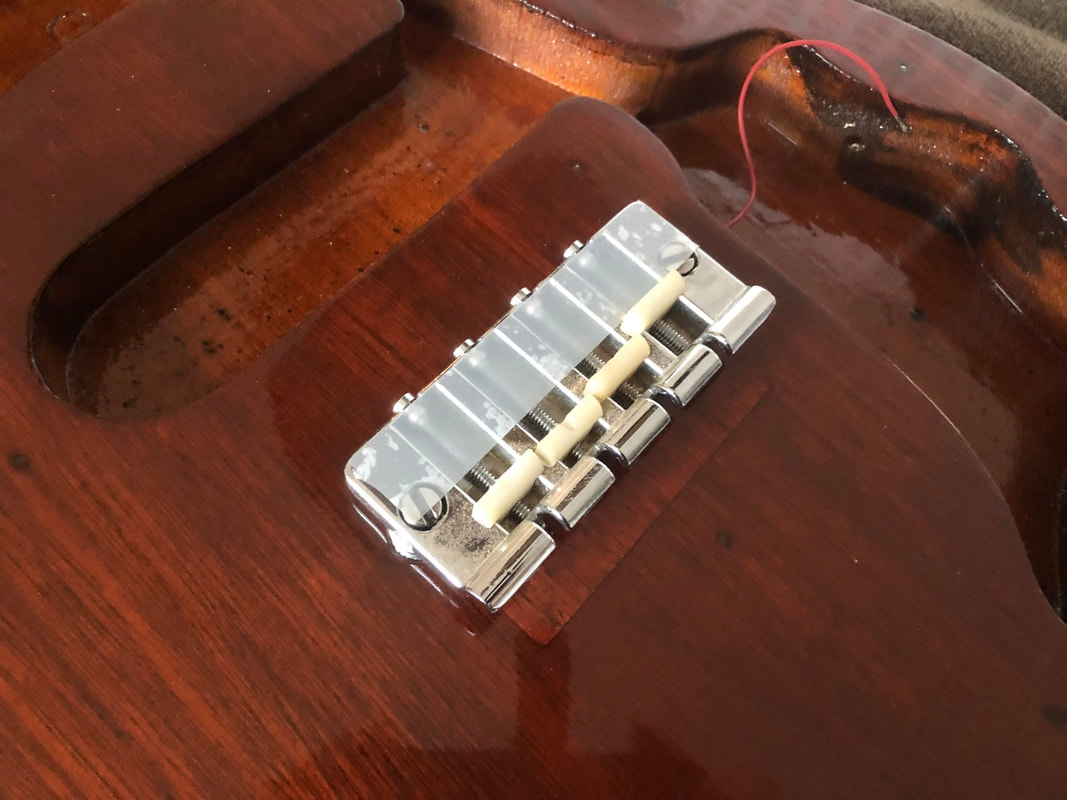

But the faulty neck angle had to be addressed. So the original two point bridge was removed. The posts and studs were taken out. Enter the Badass bridge. But that would be too high to get the action anywhere near playable. So the bridge had to be recessed into the body. Some sort of crown shaped piece of black plastic was glued onto the body to cover up the half exposed holes where the original studs had been.

But the bass was playable. The Badass bridge is a fine piece of hardware. It's just completely out of place on this bass...

The original machine heads were removed as well and replaced by lighter weight Gotoh tuners. Reason for that is no doubt the rather serious neck dive. The body is simply too thin, too small and there too much wood routed away to offer a counter weight for old school vintage large clover tuners that Gibson used back in the day.

To make the Gotoh tuners fit the holes in the headstock were drilled wider.

I have performed with this bass on several stages. But I've always been a bit reluctant to take it with me on the road because its such a rare and valuable instrument. The pictures below are from the gig I did with Stonefly, supporting for Whitesnake in Tilburg 2008.

www.talkbass.com

www.talkbass.com

www.talkbass.com

www.talkbass.com